Solar Cells:

Screen printing can print conductive paste on the solar cell sheet to form electrodes, ensuring that the battery has efficient electrical energy conversion ability and reliable electrical performance.

With the rapid development of the electronics industry, the manufacturing process of precision electronic components is also constantly innovated, screen printing as a traditional and effective printing technology, is widely used in the production of precision electronic components.

Screen printing can print conductive paste on the solar cell sheet to form electrodes, ensuring that the battery has efficient electrical energy conversion ability and reliable electrical performance.

Screen printing can accurately print conductive lines and functional layers on flexible circuit boards to ensure the reliability and performance of circuit boards, and is suitable for various types of flexible electronic devices.

Screen printing can print precise conductive patterns and electrodes on the mobile phone touch screen to ensure high sensitivity and accuracy of the touch screen and improve the user's operating experience.

Screen printing can print organic material layers and conductive layers on OLED displays, ensuring high brightness, high contrast and excellent color performance.

It can meet the printing requirements of tiny sizes and high precision, ensuring the quality and reliability of electronic products.

The printed patterns and texts are clear and delicate, which enhances the visual effect of the product.

It is suitable for a variety of electronic materials, such as plastics, glass, metal, etc.

A large number of printing tasks can be completed quickly to meet the needs of large-scale production.

Compared with other high-precision printing technologies, precision electronic screen printing has a higher cost-effectiveness.

As a mature and reliable printing technology, auto parts screen printing provides efficient, accurate and reliable solutions for the automotive manufacturing industry, helping the auto parts manufacturing industry achieve a higher level of development.

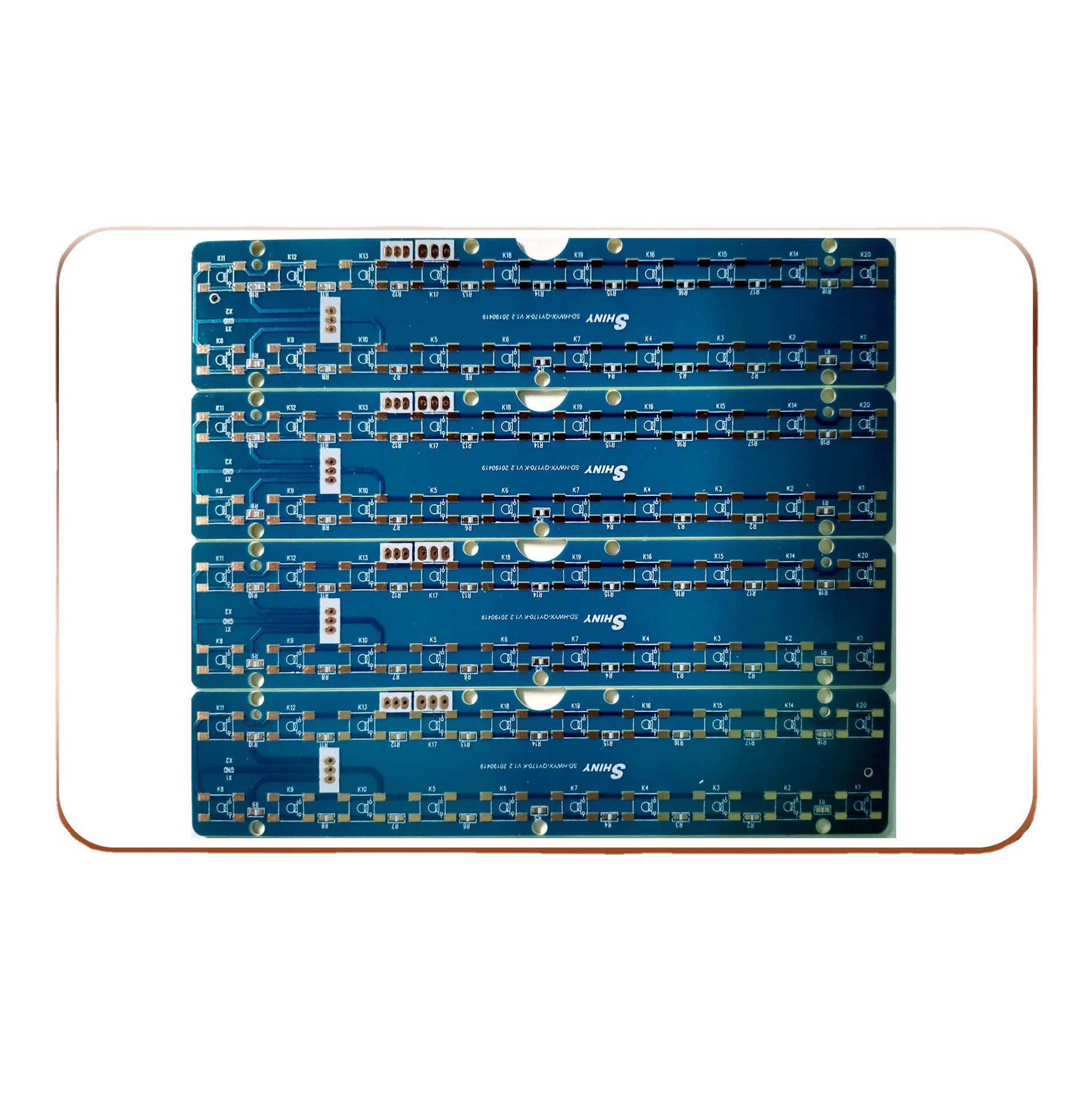

PCB circuit board screen printing is a critical technology used to create circuit patterns on printed circuit boards (PCBs). It involves transferring electronic ink onto the substrate through a screen to form precise conductive paths and circuit designs. This technique offers advantages such as high precision, low cost, and high efficiency. The process includes screen preparation, ink formulation, printing, and drying/curing. Screen selection typically considers mesh density and material, with stainless steel or polyester being commonly used. It is widely applied in the manufacturing of various electronic devices, such as computers, communication equipment, and consumer electronics. With technological advancements, screen printing will see broader applications in miniaturized and multifunctional electronic products.

Flexible circuit board screen printing is a key technology used to manufacture flexible circuit boards (FPCs). It forms a precise circuit pattern by screen printing conductive ink or other functional materials onto a flexible substrate. This technology has the advantages of high precision, low cost and strong adaptability, and can achieve mass production of complex circuits on flexible, film-like materials. Its process includes screen making, ink modulation, printing and drying and curing. Flexible circuit board screen printing is widely used in smart phones, wearable devices, medical electronics and flexible displays, meeting the development needs of modern electronic products for thinness and multi-functions.

Screen printing for mobile phone screens is a technology used to print functional patterns on phone displays. It involves precisely transferring conductive, insulating, or decorative inks onto glass or plastic substrates through a screen to form touch electrodes, borders, logos, and other designs. This technique offers high precision, efficiency, and cost-effectiveness. The process includes screen preparation, ink formulation, printing, and drying/curing. Screen printing for mobile phone screens is widely used in the production of touchscreens, display borders, and decorative patterns for smartphones, meeting the demand for aesthetics and integrated functionality in modern phones.

Screen printing for OLED displays is a key technology used in the manufacturing of OLED screens. It involves precisely transferring conductive inks, insulating inks, and luminescent materials onto the substrate through a screen to form multi-layer patterns with micron-level precision. This process features high accuracy, good thickness control, low-temperature processing, and high efficiency, making it suitable for large-area and flexible substrates. Screen printing is widely applied in the production of touch electrodes, luminescent layers, and protective layers in OLED displays, meeting the modern display technology's demands for high performance and low cost.

Screen printing is the core of process management in the manufacturing process of solar cells. Screen printing is mainly used for forming the electrodes of batteries. It uses the basic principle that the mesh holes of the graphic part of the screen can pass the slurry, while the mesh holes of the non-graphic part cannot pass the slurry. When printing, pour the slurry at one end of the screen, and use a scraper to apply a certain pressure on the slurry part of the screen while moving toward the other end of the screen. The slurry is squeezed from the mesh holes of the graphic part to the substrate by the scraper during movement to form the required pattern.

400*600mm