Home / All / Screen Printing Machines / Automatic Flat Screen Printing Machine /

Full Automatic Roll to Roll Screen Printing Machine for Ceramic Decal

Full Automatic Roll to Roll Screen Printing Machine for Ceramic Decal

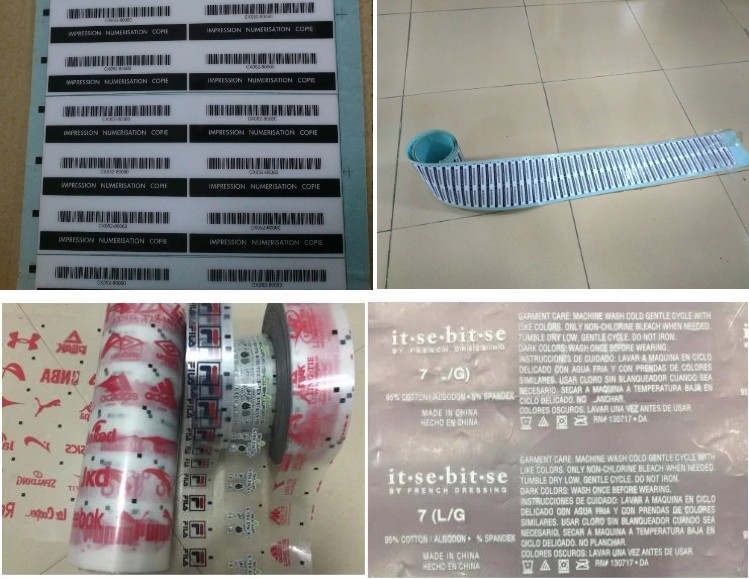

This machine is widely used in PET, OPP, PVC, IMD ,transfer paper (film), floor heating film, geothermal film, electrothermal film, color paper, film, name plate, flexible circuit board, mobile phone keys, 3 m glue, glue, film switch, trademark laser, scratch CARDS, self-adhesive stickers, paper, aluminum foil and copper foil this roll material silk screen printing, drying, and collectting.

| Categories | Automatic Flat Screen Printing Machine |

|---|---|

| Brand | TAOXING Screen Printing Machines Manufacturer |

| Model | TX-5080SP |

| Model | TX-5080SP |

| Max printing area | 500X800mm |

| Table size | 500x700mm |

| Printing Speed | 400Pcs/h |

| Max screen frame | 750x1080mm |

| Stacking Height | 300mm |

| Work-Piece Thickness | 0.1-2mm |

| Machine Weight | 2200kg |

| Worktable Displacement | ±5mm |

| Power Supply | AC380V/50Hz |

| Machine Dimension | 3500*1100*2050mm |

| Machine Weight | 950KG |

| FOB port | Ningbo |

| Terms of Payment | T/T |

| Update Time | Nov 21,2024 |

Detail Information

Introduction Fully Automatic Roll To Roll Screen Printing Machine

This machine is widely used in PET, OPP, PVC, IMD ,transfer paper (film), floor heating film, geothermal film, electrothermal film, color paper, film, name plate, flexible circuit board, mobile phone keys, 3 m glue, glue, film switch, trademark laser, scratch CARDS, self-adhesive stickers, paper, aluminum foil and copper foil this roll material silk screen printing, drying, and collectting.

Main Feature

①Feeding adopt the latest computer numerical control servo motor transmit.

②The main transmission parts adopt pneumatic device, around front and after the printing position are controlled by photoelectric eye tracking and controling, so that the machine will have high accuracy, stable feeding, automatic counting alarm, convenient adjustment, compact structure, etc.

Main performance

Main performance

①Multi-color automatic tracking and alignment, Japan Mitsubishi PLC + Germany SK color sensor control system alignment, accurate and stable color registration.

②The material pulling adopts a suction puller with uniform pulling force to solve the problem of material deviation when pulling, effectively reduce material scratches, eliminate the damage to the edge of the material caused by the pressure wheel, and make the overprint of easily deformed materials such as aluminum foil more accurate.

③Printing is automatically calculated, and the machine stops automatically when the set quantity is reached.

④There is an automatic shutdown alarm for no material and machine failure.

⑤The scraper movement is driven by a Japanese servo motor, and the ink return is the same. The printing position and speed can be set separately and arbitrarily. The ink return is uniform, the printing is horizontal, the printing is clear and consistent, and it is not easy to have color difference and missing dots.

⑥It is equipped with an automatic dust removal function to remove dust on the printed product, effectively improving the qualified rate of the product.

⑦It is equipped with a screen-off function. When printing, the screen follows the inclination of the scraper to remove the printed product. When running quickly, the fine dots are clear and not easy to stick to the screen. It is suitable for printing large-area background patterns, glue and other special inks.

⑧This machine is equipped with manual/automatic suction function, and the suction strength is adjustable.

Application Fully Automatic Roll To Roll Screen Printing Machine

Main parameters

|

Model

|

TX-R4060

|

TX-R5080

|

|

Maximum screen frame size

|

700*850mm

|

800*1150mm

|

|

Maximum printing area

|

400*600mm

|

500*800mm

|

Material thickness | 0.035-0.4mm | 0.035-0.4mm |

Feed width | 410mm | 510mm |

Scraper stroke | 600mm | 900mm |

Printing speed | 500-750m/h | 500-1000m/h |

|

Air working pressure

|

5kg/cm2

|

5kg/cm2

|

Working voltage | 3-380V AC | 3-380v AC |

Mechanical dimensions | 2400*1050*1700mm | 3100*1200*1700mm |

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content