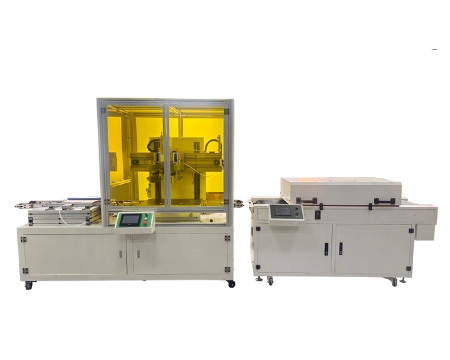

Precise Control:

Screen printing technology can achieve precise coating of the diffusion medium on the surface of rare earth permanent magnets, thereby ensuring precise control of the diffusion process. This helps to optimize the performance of the magnet and improve the consistency and stability of the product.

High Efficiency And Energy Saving:

Compared with the traditional grain boundary diffusion method, screen printing technology has higher coating efficiency and lower energy consumption. It can complete the coating of a large number of magnets in a short time, improve production efficiency and reduce production costs.

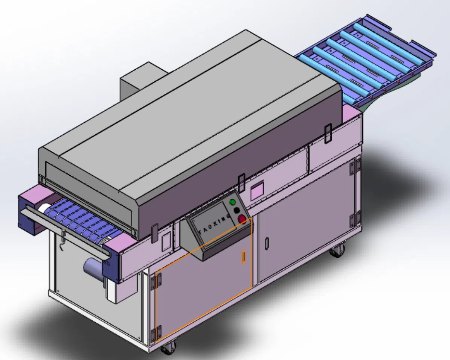

Green And Environmental Protection:

The diffusion medium and materials used in the screen printing process can be selected and optimized as needed to meet environmental protection requirements. In addition, this technology can also reduce the amount of heavy rare earth elements and reduce the impact on the environment.

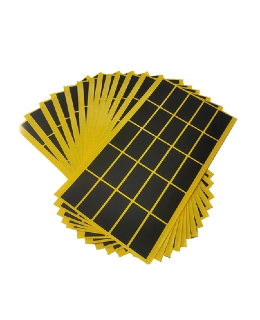

Strong Adaptability:

Screen printing technology is suitable for rare earth permanent magnets of various shapes and sizes. It can flexibly adjust the coating parameters to meet the production needs of different products. This makes screen printing have a wide range of application prospects in the production of rare earth permanent magnet grain boundary diffusion.

Environmental protection and energy saving:

Using water-based or UV curing ink, the screen printing process does not require the use of organic solvents, reducing VOC emissions and complying with environmental protection requirements.