Small Tunnel Furnace

TX-IR600

Introduce | Infrared drying tunnel is a highly efficient and energy-saving drying equipment. It adopts advanced infrared heating technology to quickly and evenly transfer heat to the surface of the material to achieve rapid drying. Its unique heating method not only improves the drying efficiency, but also effectively maintains the quality and color of the material. At the same time, the infrared drying tunnel has the advantages of easy operation, safety and reliability, energy saving and environmental protection, and is suitable for drying various materials. Whether it is screen printing, electronic product manufacturing, or metal product spraying, the infrared drying tunnel can bring you excellent drying effects, improve production efficiency, and reduce energy consumption costs. | |||

Main Models | ||||

Parameter size | Total length: 2000mm Network bandwidth: 600mm Drying area: 1500mm Temperature control: normal temperature -120℃ Total power: about 4.5KW | Total length: 8000mm Net belt width: 800mm Length of loading/unloading section: 1000mm Length of drying area: 6000mm Total power: 25KW Power supply: AC380V | Length of feeding section: 1000mm Length of cutting section: 1500mm Length of drying area: 2000mm Temperature control: Room temperature -180℃ (adjustable) Total power: 36KW Power supply: AC380V | |

Application Areas | Widely used in drying and dehumidification in industries such as screen printing, spray dyeing, electronics, and printed circuits. | Widely used in drying and dehumidification in industries such as screen printing, spray dyeing, electronics, and printed circuits. | Widely used in drying and dehumidification in industries such as screen printing, spray dyeing, electronics, and printed circuits. | Widely used in drying and dehumidification in industries such as screen printing, spray dyeing, electronics, and printed circuits. |

| Learn More | Learn More | Learn More | Learn More | |

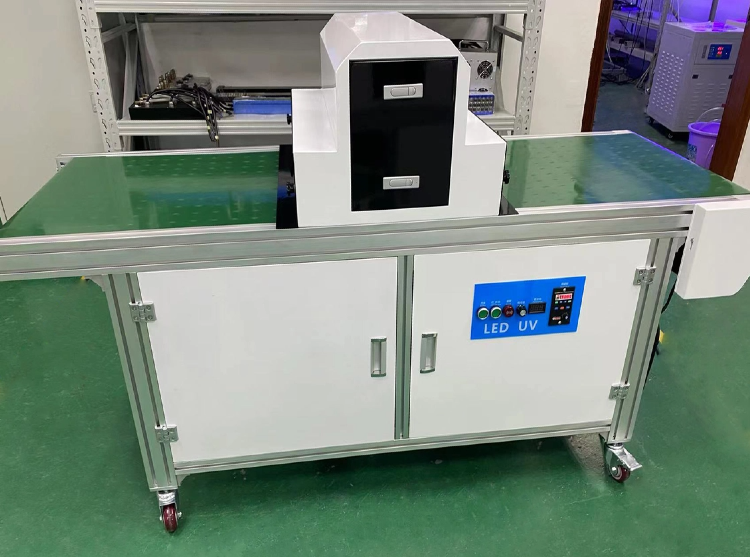

Introduce | UV curing machines play a key role in the screen printing process. It uses ultraviolet rays to irradiate the UV ink on the screen printing plate, causing the photoinitiator in the ink to rapidly undergo a polymerization reaction to achieve rapid curing of the ink. This process not only improves the quality and durability of prints, but also significantly shortens curing time and increases production efficiency. At the same time, the curing process of the UV light curing machine does not require additional heating, is energy-saving and environmentally friendly, and meets the needs of modern green production. Therefore, UV light curing machines have become indispensable and important equipment in the screen printing process. | |||

Main Models |  Flat UV Curing Machine TX-UV600 / TX-UV800 |  LED-UV Curing Machine TX-LED UV800 |  Round surface UV Curing Machine TX-UV200PY |  Portable LED UV Curing Machine TX-LED UV400 |

Parameter Size | Power supply: 380V/50HZ Power: 5.6KW*2 sets of lights Total power: 13KW Conveyor belt height: 750mm Conveying speed: 1-25m/min Network bandwidth: 80cm Total length: 250cm Dimensions: 250*105*165cm | Voltage: AC220V Power: 3KW Net belt width: 800mm Conveying speed: 5-25m/min Total length: 2000mm Dimensions: 2000*1000*1250mm | Maximum optical firmware size: Φ200*300mm Conveyor belt width: 200mm Conveyor speed: 1-10m/min Supply voltage: AC380V Lamp power: 5KW Total power: 5.4KW Dimensions: 2500*900*1350mm Weight: 180kg | Power: 800W Dimensions: L1250×W400×H1000mm Conveying speed: 3-30m/min Frequency conversion speed control transmission width: 300mm Power regulation: 0-100% adjustable Light intensity: 200mw/cm² |

Application Areas | Mainly used for UV curing of UV inks for various printed materials and hardware coatings. | It is mainly used for UV adhesive curing in display screens, electronic medical, instrumentation and other industries; UV coating curing in home appliances, automobiles and other industries; UV ink curing in printing, packaging and other industries. | Mainly used for UV curing of printed UV inks on various bottle-shaped, barrel-shaped, and curved surfaces. | Used for UV curing of UV glue on coatings of electronic products, PCB circuit boards and other products. |

| Learn More | Learn More | Learn More | Learn More | |

Introduce | Vertical drying box is an efficient and practical drying equipment. With its unique vertical structure design, it achieves fast and uniform drying effect. It adopts advanced heating technology, can quickly reach the set temperature, and maintain stability to ensure the quality of material drying. At the same time, the vertical drying box also has the advantages of energy saving and environmental protection, simple operation, safety and reliability, and is suitable for drying a variety of materials. Whether it is food processing, pharmaceutical or chemical industry, the vertical drying box can provide you with excellent drying solutions, helping you improve production efficiency and create greater value. |

Main Models |  Vertical Drying Oven TX-KXA |

Parameter Size | Studio size: 900*1200*1600mm Dimensions: 1300*1600*2350mm Operating temperature: normal temperature -180℃ Maximum temperature: 180℃ (adjustable) Working voltage: 380V/50HZ |

Application Areas | It is suitable for quick drying of solvent-based inks and general drying of moisture-containing items, such as paper printing, chemical products, glass, plates, PVC, metal nameplates, etc. |

| Learn More |

TAOXING special screen printing machine is China's leading manufacturer and supplier of special screen printing machines.

More than 10,000 devices installed and operating in dozens of industries. We have developed multiple patented and proprietary products that continue to provide cost-effective and simple solutions for automating flat and cylindrical screen printing production processes in a variety of applications, including glass, electronics, bottles, ceramics, automotive , print advertising, etc.

Our highly skilled staff and expert engineers provide your team with the tools and expertise needed to deliver decorative products faster, better and at a lower cost.

About TAOXING