Home / All / Screen Printing Machines / Automatic Flat Screen Printing Machine /

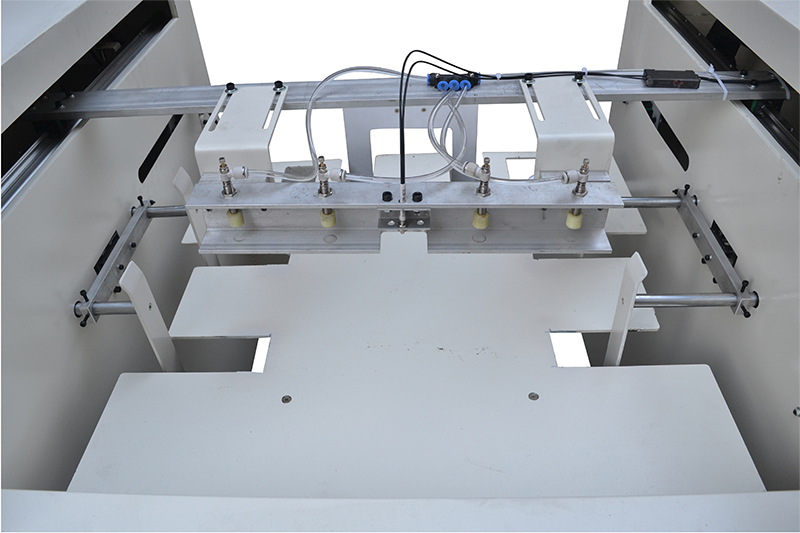

Taoxing Automatic Collection Machine TX-SLJ650 For Screen Printing

Taoxing Automatic Collection Machine TX-SLJ650 For Screen Printing

This automatic collection machine is suitable for the collection, arrangement and placement of substrates such as stickers, credit cards, ceramic decals, films, gold and silver cardboard, metal sheets, and PVC.

| Categories | Automatic Flat Screen Printing Machine |

|---|---|

| Brand | TAOXING Screen Printing Machines Manufacturer |

| Model | TX-SLJ650 |

| Maximum receiving size | 650*480mm |

| Minimum receiving size | 480*320mm (smaller size can be customized) |

| Material thickness | 0.2-1mm |

| Feeding height | 895±25mm (matching front conveying) |

| Fastest receiving speed | 1500sheets/hour |

| Transmission system | Linear slide rail |

| Total power | 2KW |

| Weight | 100kg |

| Dimension | 1150*1080*895mm |

| FOB port | Ningbo |

| Terms of Payment | T/T |

| Update Time | Nov 21,2024 |

Detail Information

Introduction

Application:

This automatic collection machine suitable for the collection, arrangement and placement of substrates such as stickers, credit cards, ceramic decals, films, gold and silver cardboard, metal sheets, and PVC.

Specification

Model: TX-SLJ650

Material thickness: 0.2-1mm

Maximum receiving size: 650*480mm

Minimum receiving size: 480*320mm (smaller size can be customized)

Feeding height: 895±25mm (matching front conveying) Fastest receiving speed : 1500sheets/hour

Transmission system: Linear slide rail

Total power: 2KW

Weight : 100kg

Dimensions: 1150*1080*895mm

Features

1. After the paper pulling system adopts the suction cup to suck the product, the stepping motor quickly drags the product to the set position, immediately releases the product, returns to the original position, and waits for the next piece.

2. Special photoelectric device is used for product detection.

3. The lifting of the paper pile is controlled by the lifter, and it will automatically drop according to the number of materials received (the number of sheets and time can be set to drop).

4. Equipped with adjustable feet, the adjustment range is 20~30mm.

5. The transmission system adopts toothed synchronous belt, and the track adopts linear slide rail.

7. There is a special air pump for the suction paper pulling material.

Machine image

Application

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content