Screen Printing Consumables and Accessories

As a widely used printing technology, screen printing consumables and accessories are the key to ensuring printing quality and efficiency. They mainly include screen printing plates, inks, scrapers, cleaning agents, screen frames and tension meters. The screen printing plates are used to carry patterns and determine printing accuracy; inks give the work color and durability; scrapers control ink distribution and affect printing effects; cleaning agents keep the equipment clean and extend its service life; screen frames support the screen to ensure stability; tension meters are used to measure screen tension and ensure printing flatness. These consumables and accessories work together to form the cornerstone of screen printing, meeting the printing needs of different materials and precision requirements, and promoting the continuous innovation and development of screen printing technology.

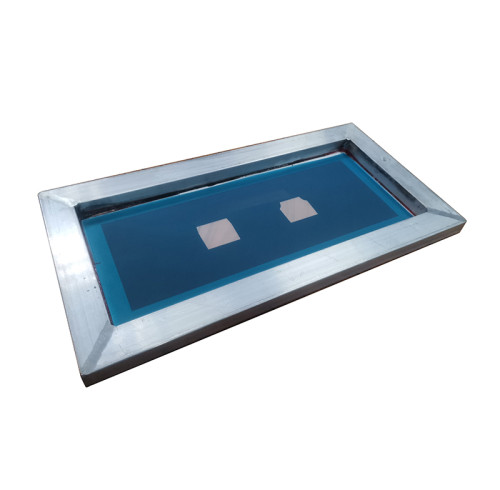

Screen Printing Frame

The silk screen printing frame is a vital component for achieving precise and consistent prints. Constructed with durable aluminum or wooden frames, it provides stability and long-lasting performance. The high-quality mesh is tightly stretched across the frame to ensure accurate ink transfer and sharp details. Available in various mesh counts, it suits a wide range of applications, from fine-detail designs to bold, solid prints. Ideal for use on textiles, paper, plastics, and more, the screen printing frame is easy to clean and reuse, making it a reliable choice for professionals and hobbyists alike. Achieve flawless results with every project!

Screen Printing Ink

Screen printing ink, commonly known as silk screen ink, is a specialized type of ink used in the screen printing process. It is formulated to deliver vibrant colors, excellent adhesion, and durability on a variety of surfaces, including textiles, paper, glass, metal, and plastics. Screen printing inks are available in various types, such as solvent-based, water-based, UV-curable, and plastisol, each catering to specific applications and material requirements. They are characterized by their ability to produce bold, opaque prints with a high level of detail and resistance to wear and environmental conditions. Widely used in industries like textiles, advertising, and packaging, screen printing ink is a versatile and essential component in achieving high-quality printed designs.

Ink Thinner

Screen cleaning agent

Printing Scraper

A screen printing scraper is an essential tool used in the screen printing process to evenly spread ink across the screen and onto the substrate. Typically made of a durable polyurethane blade attached to a wooden or aluminum handle, squeegees come in various shapes, hardness levels, and sizes to accommodate different printing needs. The blade's edge profile—straight, rounded, or beveled—affects the ink deposit thickness and printing precision. Squeegees are widely used in industries like textiles, electronics, and graphics, ensuring consistent and high-quality prints. Proper maintenance and selection of the squeegee greatly enhance printing efficiency and durability.

Vacuum suction platform

A vacuum suction platform is a specialized device designed for securely holding objects in place using vacuum pressure. It is widely utilized in industries such as manufacturing, woodworking, engraving, and electronics assembly, where precision and stability are critical.

The platform features a flat surface with strategically placed suction holes connected to a vacuum pump. When activated, the vacuum creates a strong holding force, ensuring the workpiece remains stationary during machining, cutting, or inspection processes.

Known for its efficiency and versatility, the vacuum suction platform minimizes the need for mechanical clamps, reducing setup time and improving operational accuracy. Its robust design ensures reliable performance in demanding applications.