Home / All

Screen Printing Machines and Related Equipment

Screen Printing Machines

Screen printing machine is a type of printing machine that uses screen printing plates for printing. Screen printing machine is a machine that prints text and images, and is a general term for machines or equipment used to produce printed materials

Pad Printer

Pad printers are widely used in many fields, including plastics, toys, electronics, stationery, leather, ceramics, etc. It can efficiently and accurately transfer patterns and texts to achieve personalized customization and identification of products. In industrial production, pad printers provide high-quality decorative effects for products with their high precision and stability. At the same time, it also brings more creative space for product design, making products more colorful and meeting the diverse needs of consumers.

Thermal Transfer Machine

Thermal transfer machines are a type of efficient printing equipment that works by transferring patterns from thermal transfer films to various materials through heating and pressure. They are widely used in textiles, packaging, advertising and other fields to achieve personalized customization and high-quality printing. The thermal transfer process has the advantages of bright colors, clear patterns, strong adhesion, etc., while being easy to operate, environmentally friendly and pollution-free. Thermal transfer machines are a powerful assistant to modern printing technology, bringing efficient and high-quality printing experience to all walks of life.

Post-printing drying equipment

Screen printing drying and curing equipment is a key part of the screen printing process, integrating drying and curing functions. It adopts an efficient heating system to ensure that the printed matter is dried quickly and evenly, and at the same time, precise temperature control is used to achieve stable solidification of the pattern. The equipment has compact structure, easy operation, safety and reliability, and is suitable for all kinds of screen printing products. Its excellent drying and curing effect can significantly improve the quality and durability of printed matter. Whether it is industrial production or artistic creation, screen printing drying and curing equipment is your ideal choice.

Prepress Equipment

Introducing our state-of-the-art Silkscreen Printing Platemaking Equipment, designed for precision and efficiency in the graphic arts industry. This equipment combines advanced technology with user-friendly interfaces, ensuring accurate image transfer onto various substrates. Its high-resolution capabilities guarantee crisp, detailed results, while the automated processes streamline production, reducing labor costs and enhancing productivity. Equipped with durable components and precision mechanisms, it ensures longevity and reliability in fast-paced production environments. Whether for packaging, advertising, or electronics, our Silkscreen Printing Platemaking Equipment delivers exceptional quality and versatility, empowering businesses to stand out in a competitive market.

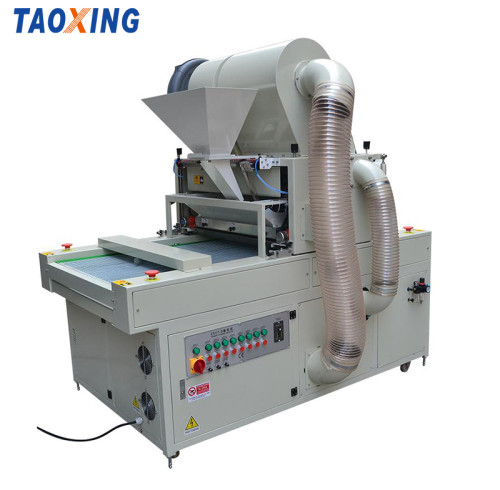

Powder Coating Machine

The Automatic Powder Spraying Machine is a state-of-the-art device designed for efficient and precise application of powder coatings. Ideal for industrial use, it features advanced controls for uniform powder distribution, reducing waste and ensuring consistent quality. The machine's robust construction and user-friendly interface make it suitable for high-volume production lines, enhancing productivity and minimizing downtime. Its adaptability to various powder types and workpieces makes it a versatile solution for diverse manufacturing needs.

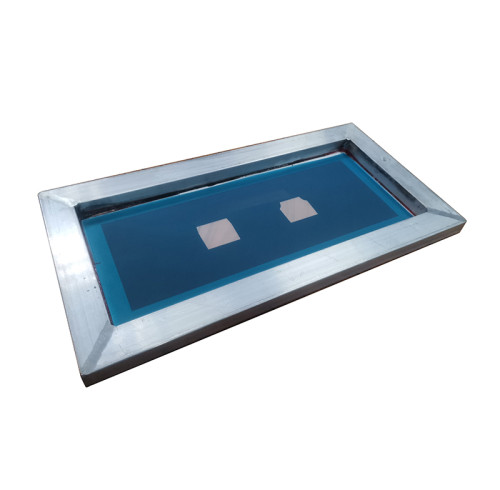

Screen Printing Consumables and Accessories

As a widely used printing technology, screen printing consumables and accessories are the key to ensuring printing quality and efficiency. They mainly include screen printing plates, inks, scrapers, cleaning agents, screen frames and tension meters. The screen printing plates are used to carry patterns and determine printing accuracy; inks give the work color and durability; scrapers control ink distribution and affect printing effects; cleaning agents keep the equipment clean and extend its service life; screen frames support the screen to ensure stability; tension meters are used to measure screen tension and ensure printing flatness. These consumables and accessories work together to form the cornerstone of screen printing, meeting the printing needs of different materials and precision requirements, and promoting the continuous innovation and development of screen printing technology.

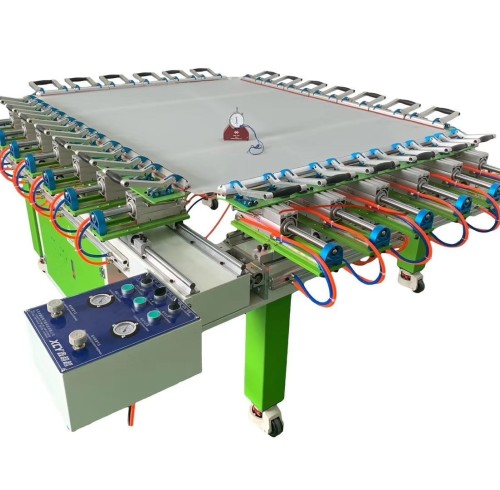

Screen Printing Auxiliary Equipment

Our silkscreen printing auxiliary equipment is designed to optimize the printing process, offering precision, efficiency, and ease of operation. This versatile lineup includes exposure units, drying racks, screen stretchers, and ink mixers, all crafted with durable materials to ensure long-term reliability. With user-friendly controls and innovative features, our equipment enhances print quality, reduces production time, and minimizes waste. Whether for textiles, posters, or specialty materials, our solutions cater to both beginners and professionals in the screen-printing industry. Trust our auxiliary equipment to deliver consistent, high-quality results, empowering your creativity and streamlining your workflow.