Home / All / Screen Printing Machines / Semi-Automatic Flat Screen Printing Machine /

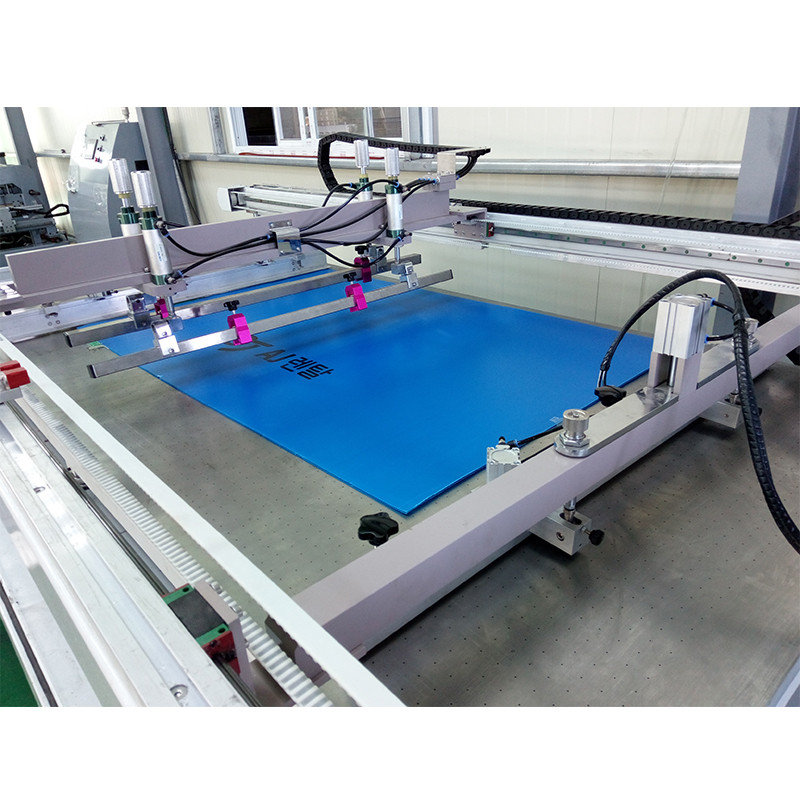

Taoxing Four-column Sliding Table Screen Printing Machine TX-1224ST-P

Taoxing Four-column Sliding Table Screen Printing Machine TX-1224ST-P

This large-scale glass screen printing machine can be used for large-scale product printing processes such as large-scale single-color glass printing, large-scale multi-color glass printing, etc. Since the work surface of this printing machine is very large, it is very suitable for some large-scale products to choose this type of machine.

Detail Information

Introduction

Application:

This large-scale glass screen printing machine can be used for large-scale product printing processes such as large-scale single-color glass printing, large-scale multi-color glass printing, etc. Since the work surface of this printing machine is very large, it is very suitable for some large-scale products to choose this type of machine.

Features

1. The ink on the surface of the printed product is very uniform.

2. Because the work surface is relatively large, the production staff has a very large space for operation, and it is very convenient to take and discharge materials.

3. The function of the machine is very perfect, fully satisfying the diversified operation.

4. The screen printing of single-color glass and multi-color glass is diversified.

5. The control system adopts Japan's Mitsubishi PLC and electrical components, and the photoelectric sensor adopts Taiwan brand with high precision and fast response. The operating environment adopts the man-machine interface, which can be upgraded with the upgrade of the product, and is equipped with a fault maintenance prompt system, which is convenient for maintenance.

6. The pneumatic components of the printing and the whole machine are composed of Taiwan Airtec pneumatic components, which are durable and stable.

7. The printing motion system adopts the brand linear precision guide rail and runs with the wear-resistant polyester synchronous belt, which has no noise, long life and stable operation.

8. The printing drive adopts frequency conversion deceleration motor, stepless speed regulation, and the speed of scraper and oil return knife can be freely set.

9. The printing table adopts the combination of aluminum alloy profiles, honeycomb combination, and the surface is bonded with stainless steel sheets. It is processed by special technology. The surface is flat and smooth. It is equipped with suction and blowing devices to ensure strong suction printing.

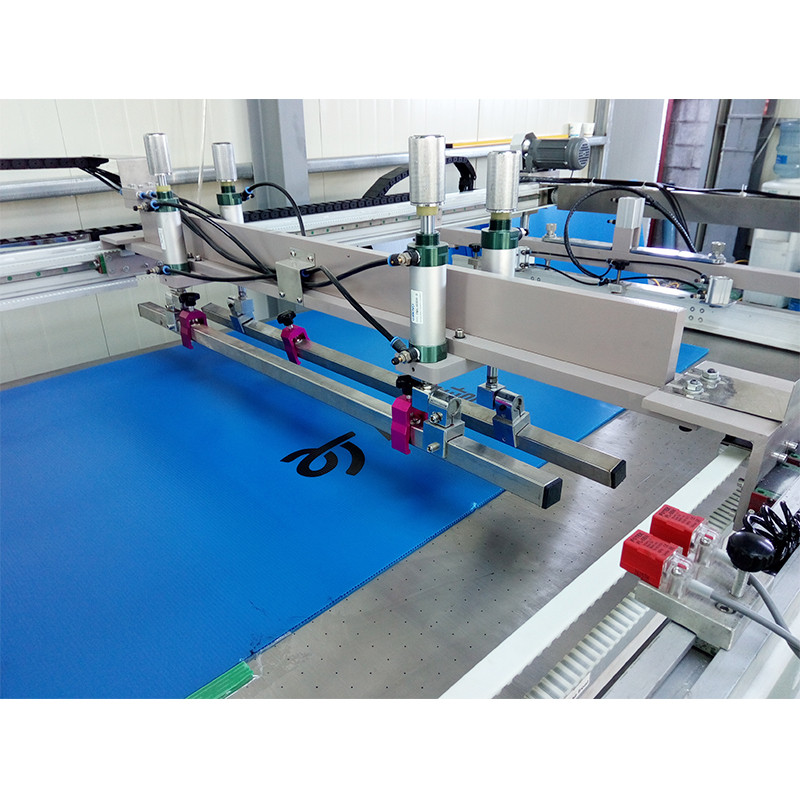

10. Pneumatic locking is adopted for all printing screen frame locking, and auxiliary manual locking is used to prevent screen shifting caused by unstable air pressure. It is easy to operate, labor-saving and fast. The screen frame adjustment is provided with a fine-scale indication, and all use a fine-scale handle. The adjustment is precise, convenient and fast.

11. There are 2 high-pressure suction fans in the printing panel, and a silencer is installed, which has strong suction and low noise.

12. The squeegee seat can be moved independently according to the printing area. The squeegee and ink-covering knife use quick ink filling, and can be adjusted at an angle of 0-45 degrees. The squeegee adopts a super-induction constant pressure structure. After the pressure is set, the The thickness of the printed matter can be automatically stabilized to assist.

13. Synchronous off-plate structure design cooperates with the scraping action to improve the plate frame synchronously, without generating shock waves and elastic fatigue. When scraping various inks of different viscosities and different tension screens, no shadows, deformation, sticking, and import separation will occur. Plate cylinder, suitable for all kinds of high-precision printing. (Can adjust the spacing with the size version)

14. Continuous scratch printing can be set for 1-2 times without moving the panel, which can make the printed object more three-dimensional.

15. The whole machine is equipped with a safety emergency stop button and multiple safety protection devices to ensure the personal safety of the operator.

Specification

Model | TX-1224ST-P | |||||||

Printing Table Size | 1400*2600mm | |||||||

Printing Thickness | ≤30mm | |||||||

Max Printing Area | 1200*2400mm | |||||||

Printing speed | 300 pcs/h | |||||||

Maximum screen frame size | 1600*2800mm | |||||||

Stacking Height | 300mm | |||||||

Worktable Displacement | ±10mm | |||||||

Power Consumption | 380V/50HZ /5.6KW | |||||||

Printing pressure | 6~8 kfg/c㎡ | |||||||

Machine Dimension | 1160*910*2150mm | |||||||

Machine Weight | 1000KG | |||||||

Machine image

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content