Home / All / Screen Printing Machines / Semi-Automatic Flat Screen Printing Machine /

Double Stations Semi Automatic Flat Silk Screen Printing Machine TX-6080ST-SP for Aluminium Plate

Double Stations Semi Automatic Flat Silk Screen Printing Machine TX-6080ST-SP for Aluminium Plate

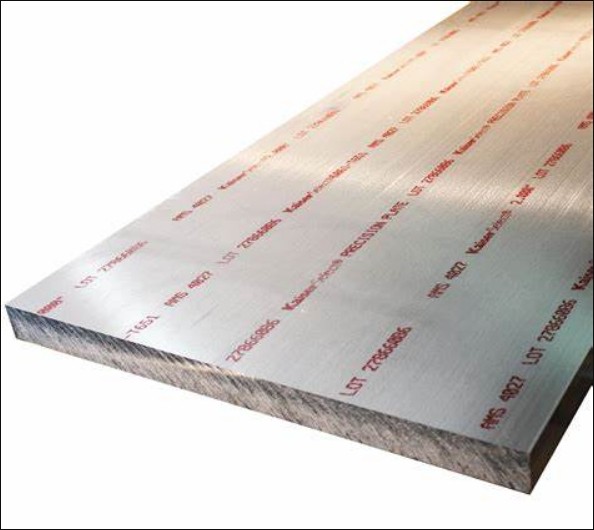

This machine is suitable for color printing and monochrome printing of medium-sized posters, three-dimensional POP, motorcycle, bicycle body stickers, glass, building materials metal plates, plastic plates, acrylic, wood and circuit boards, aluminum strips, square tubes, etc.

Detail Information

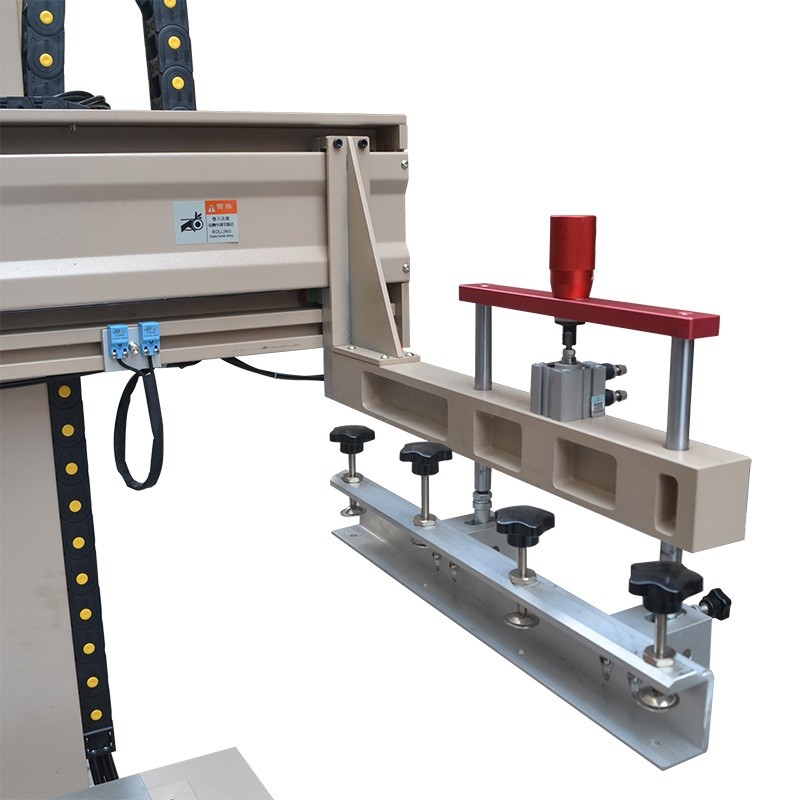

Introduction Vertical High Precision Double Sliding Table Screen Printing Machine

Application:

This machine is suitable for color printing and monochrome printing of medium-sized posters, three-dimensional POP, motorcycle, bicycle body stickers, glass, building materials metal plates, plastic plates, acrylic, wood and circuit boards, aluminum strips, square tubes, etc.

Features

(1) The lift is guided by a servo motor and a high-precision linear guide rail, which is convenient for electronic adjustment of the screen distance, stable operation without impact, and high repeat printing accuracy.

(2) The ink scraping and ink return use the servo motor to work with the linear guide rail, the printing is stable and the stroke is accurate.

(3) The exquisite cast aluminum head is guided by double guide rods, which is easy to adjust, runs smoothly and is durable.

(4) The screen frame adopts the handle to clamp the frame, which is easy to install and disassemble, the two arms can slide left and right on the beam, and the size of the screen frame is convenient to change.

(5) PLC and man-machine interface control, various functions, meet the requirements of numerical control, standardization and humanization.

(6) The adjustment has emergency stop switch, automatic fault display function, safety system reset, and safety lever touches the emergency stop device.

(7) Double working table servo control alternate left and right movement, printing and up and down at the same time, higher efficiency.

(8) The whole machine is equipped with safety protection device + photoelectric protection + emergency stop switch, safety system reset, touch emergency stop device, comprehensive personal protection, multiple protection, safe, stable and reliable.

Specification

Model | TX-6080ST-SP | |||||||

Table Size | 700*1000mm | |||||||

Printing Thickness | 30mm | |||||||

Max Printing Area | 600*800mm | |||||||

Printing speed | 600 pcs/h | |||||||

Maximum screen frame size | 1000*1400mm | |||||||

Working station | 2 | |||||||

Servo system | 3 sets | |||||||

Power Consumption | 220V/3.6KW | |||||||

Air pressure | 4.0~6.0 kfg/c㎡ | |||||||

Machine Dimension | 2800*1410*1650mm | |||||||

Machine Weight | 700KG | |||||||

Machine image

Printing samples

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content