Home / All / Screen Printing Machines / Semi-Automatic Flat Screen Printing Machine /

Double Servo Motor Flat Screen Printing Machine TX-2030SF for Metal and Plastic Signs

Double Servo Motor Flat Screen Printing Machine TX-2030SF for Metal and Plastic Signs

Double Servo Flat Screen Printing Machine is suitable for electronic panels, glass panels, ceramic substrates, metal plates, PCB boards, and other products printing, especially for the small items which need high accuracy printing.

Detail Information

Introduction

Application

Double Servo Flat Screen Printing Machine is suitable for electronic panels, glass panels, ceramic substrates, metal plates, PCB boards, and other products printing, especially for the small items which need high accuracy printing.Specification

Max Print Area: 20*30cm

Working Table: 30*40cm

Screen Frame Size Max: 50*70cm(OD)

Printing Accuracy: ±0.02mm

Substrate Thickness (Printable): 200mm

Max Printing SPeed: 1400(PCS/H)

Power Supply: 220V/1.5KW

Air pressure: 0.5-0.7Mpa

Features

★Main performance

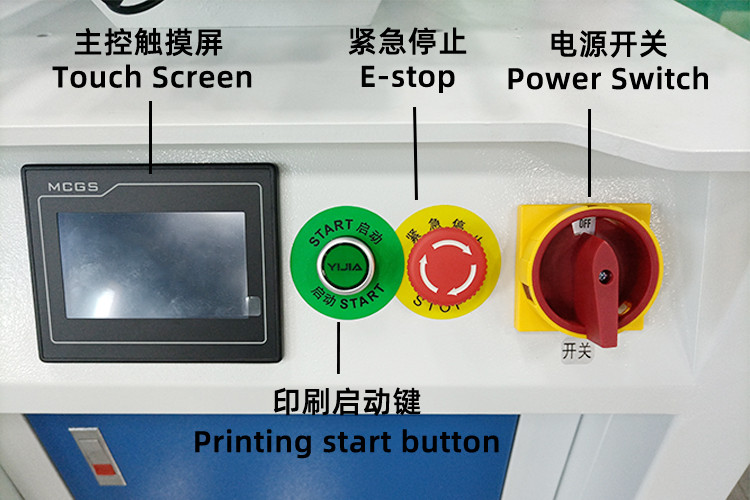

① Mitsubishi PLC program PLC program control circuit, human-machine interface control, humanized operation.

② Vertical structure, screen vertical up and down, printing head left and right movement.

③ Printing and screen lifting use independent drive source, coordinated action, stable and adjustable speed.

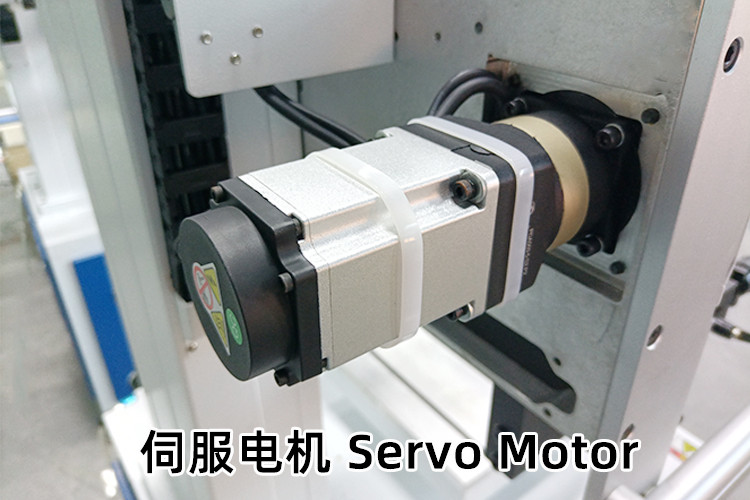

④ Panasonic servo system drives printing knife holder, photoelectric eye controls stroke, independent adjustment.

⑤ Printing drives Panasonic servo motor, stable action.

⑥ The printing platform is equipped with precision fine-tuning handles in horizontal and vertical directions, accurate fine-tuning, and convenient color registration.

⑦ There are three printing modes: manual/semi-automatic/fully automatic, and the indirect time of automatic printing is digitally controlled (1~9 seconds).

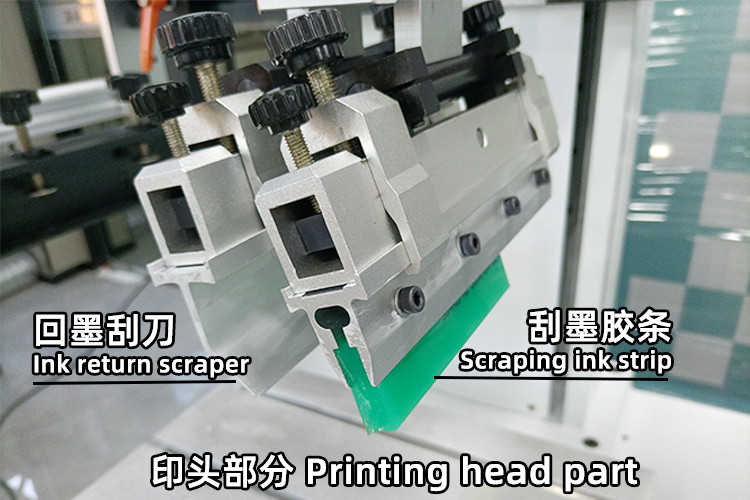

⑧ Independently designed head lifting device, easy loading and unloading of scraper/ink return knife, screen and cleaning of screen.

⑨ The left and right screen clamp arms are equipped with plate spacing adjustment device, which is easy to adjust.

⑩ The angle and balance of scraping and ink return can be adjusted.

⑪ The printing table adopts a vacuum suction work surface to facilitate the fixing of printing sheets.

Machine image

Printing samples

Plastic Labels

Ceramic substrate

Solar Photovoltaic Panels

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content