Semi-automatic Thick Film Printing Machine: A Powerful Assistant For High-precision

Introduction

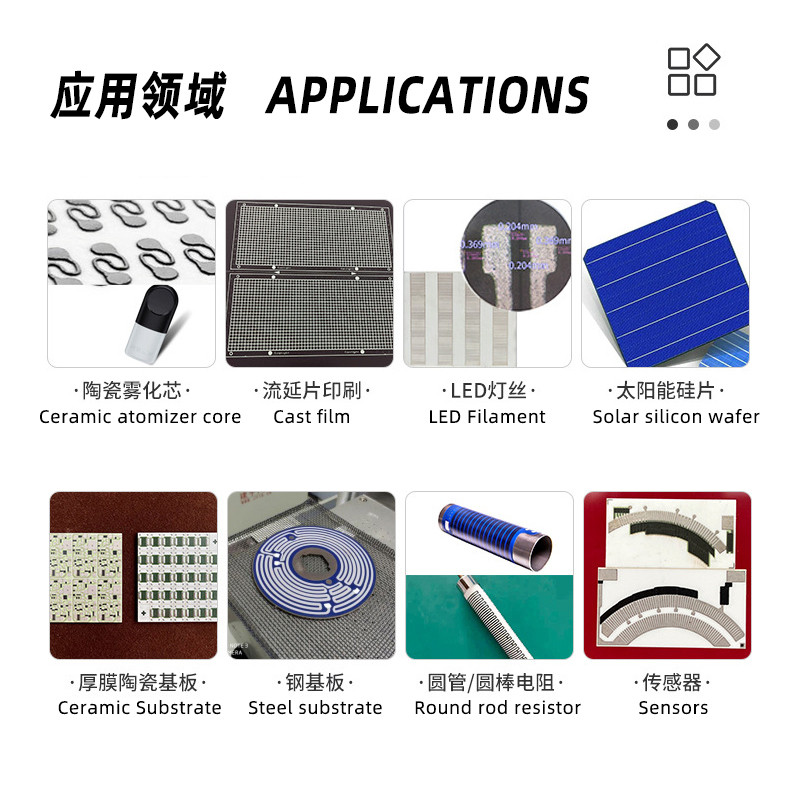

In today's industrial production field, the precision and quality of printing technology play a vital role in the performance and quality of many products. As an advanced printing equipment, the semi-automatic thick film printer has become a powerful assistant for achieving high-precision printing with its unique technical advantages. It is widely used in electronics, new energy, ceramics and other industries, providing strong support for the development of these industries.

I. Working principle and technical characteristics of semi-automatic thick film printing machine

The working principle of the semi-automatic thick film printer is based on screen printing technology. The thick film slurry is squeezed through the pattern area on the screen by a scraper to form a predetermined thick film pattern on the printed substrate. Its key technical features include the following aspects:

1. High-precision scraper system

The scraper is the core component for controlling the thickness and uniformity of the printed film. The semi-automatic thick film printer is equipped with a high-precision scraper adjustment device that can accurately control the pressure, angle and speed of the scraper. Precise adjustment of the scraper pressure can ensure that the thick film slurry passes through the screen evenly during the printing process, thereby forming a film layer of uniform thickness on the substrate. Slight adjustments to the scraper angle can affect the amount of slurry transferred and the clarity of the printed lines. The right angle can make the edges of the printed pattern sharper and the lines more uniform. At the same time, the stability of the scraper speed also has an important impact on the printing quality. A stable scraper speed helps to ensure the uniformity of the film thickness and the repeatability of the pattern.

2. High-quality screen printing plate

The quality of the screen directly determines the accuracy and resolution of the printed pattern. The screen used by the semi-automatic thick film printer usually adopts high-precision screen material, and its mesh uniformity and consistency are very high. When making the screen, advanced plate making processes such as photolithography are used to accurately produce complex and fine patterns. In addition, the tension control of the screen is also very critical. The appropriate tension can ensure the flatness and stability of the screen during the printing process, avoid problems such as pattern deformation, and thus ensure high-precision replication of the printed pattern.

3. Precision printing platform and positioning system

The printing platform provides a stable support for the substrate to be printed, and its flatness and rigidity are crucial to ensure printing accuracy. The printing platform of the semi-automatic thick film printer is usually manufactured using high-precision processing technology, with extremely small surface flatness errors, which can effectively prevent the substrate from warping or displacement during the printing process. At the same time, it is equipped with a precise positioning system that can quickly and accurately position the substrate at the predetermined printing position, ensuring high repeatability of the pattern position each time it is printed. Even in the case of multiple consecutive printings, the precise alignment of the pattern can be guaranteed to meet application scenarios with extremely high requirements for printing accuracy.

4. Accurate drying control system

In the thick film printing process, the printed slurry needs to be dried to solidify and form a stable film structure. The drying control system of the semi-automatic thick film printer can accurately control parameters such as drying temperature, time and wind speed. According to the different thick film slurry characteristics and printing requirements, precise drying control can ensure that the slurry is solidified under appropriate conditions, avoiding film quality problems caused by insufficient or excessive drying, such as poor film adhesion and increased surface roughness, thereby ensuring high precision and high quality of printed products.

II. Application advantages of semi-automatic thick film printing machine in various industries

1. Electronics industry

In electronic circuit manufacturing, the requirements for printing accuracy are extremely high. Semi-automatic thick film printing machines can accurately print thick film circuit patterns such as resistors, capacitors, and inductors in electronic components. For example, in the production process of multilayer ceramic capacitors (MLCC), high-precision printing can ensure that the thickness and shape of each layer of electrodes are uniform, thereby ensuring that the electrical performance of the capacitor is stable and reliable. In addition, in the manufacturing of printed circuit boards (PCBs), semi-automatic thick film printing machines can accurately fill tiny lines and vias, improve the wiring density and signal transmission performance of PCBs, and meet the needs of electronic products that continue to move toward miniaturization and high performance. development needs. Compared with traditional printing methods, the application of semi-automatic thick film printing machines in the electronics industry can significantly improve product yields, reduce production costs, and improve the overall performance and reliability of electronic products.

2. New energy industry

For the manufacture of solar cells, the printing quality of electrodes directly affects the photoelectric conversion efficiency of the battery. Semi-automatic thick film printers can accurately print highly conductive silver paste and other materials on the surface of silicon wafers to form uniform and dense electrodes. By precisely controlling the printing film thickness and pattern accuracy, the contact area between the electrode and the silicon wafer can be increased, the contact resistance can be reduced, and the photoelectric conversion efficiency of solar cells can be improved. In the field of battery manufacturing for new energy vehicles, high-precision printing technology is also required to prepare key components such as battery electrodes and electrolyte layers. The application of semi-automatic thick film printers can meet these strict precision requirements, providing strong technical support for the development of new energy vehicles and promoting the progress of the new energy industry.

3. Ceramic industry

Semi-automatic thick film printers have shown unique advantages in ceramic decoration and functional ceramic manufacturing. In the field of ceramic decoration, it can print exquisite patterns and colors to meet consumers' demand for personalized, high-quality ceramic products. Through high-precision printing technology, it can achieve the delicate presentation of complex patterns, making ceramic products have higher artistic value and market competitiveness. In the manufacture of functional ceramics , such as ceramic sensors, ceramic heating elements, etc., semi-automatic thick film printers can accurately print thick film layers with specific functions to ensure the performance stability and reliability of ceramic components. Its high-precision printing capability enables ceramic products to reach a higher level in both functional realization and appearance decoration, expanding the development space of the ceramic industry.

III. Practical application case analysis

1. An electronic component manufacturing company

This company mainly produces various types of electronic chips and integrated circuit modules. Before the introduction of semi-automatic thick film printing machines, it used traditional manual printing methods. The printing accuracy of the products was low, the yield rate was only about 70%, and the production efficiency was low, seriously Affects the market competitiveness of enterprises. After the introduction of the semi-automatic thick film printing machine, by optimizing the printing process parameters and using its high-precision scraper system and precise positioning system, the printing accuracy of the product has been greatly improved, and the film thickness uniformity error is controlled within a very small range, making it a good product. The rate increased to over 90%. At the same time, production efficiency has also increased by 40%, effectively reducing production costs. The company's product quality and market share have been significantly improved, bringing considerable economic benefits to the company.

2. A solar cell manufacturer

This company faces the dual challenge of improving photoelectric conversion efficiency and reducing production costs in the solar cell electrode printing process. The original printing equipment cannot meet the requirements for electrode printing accuracy, resulting in unsatisfactory battery performance. After using a semi-automatic thick film printing machine, the thickness and line accuracy of the electrodes have been significantly improved through precise printing control, which has increased the photoelectric conversion efficiency of the battery by about 0.6% on average. In the case of mass production, this efficiency improvement has brought significant economic benefits to the company. At the same time, the improvement in product quality has also enhanced the company's competitiveness in the market, helping the company occupy a more favorable position in the solar cell market. status.

3. A high-end ceramic products company

The company focuses on the production of artistic ceramics and high-end functional ceramic products, and has extremely high requirements for the printing accuracy and color reproduction of ceramic surface patterns. Before using the semi-automatic thick film printer, due to insufficient printing accuracy, the pattern details of the products were not clear enough, and the color layering was not strong, which affected the artistic value and market price of the products. After the introduction of the semi-automatic thick film printer, with its high-quality screen plate and precise printing control, it can perfectly present the details and colors of the design patterns, greatly improve the artistic quality of the products, and the market price has also increased accordingly. At the same time, in the manufacture of functional ceramic products, high-precision printing ensures the performance stability of the functional layer, which makes the company's products widely recognized and praised in the high-end market, and promotes the company's brand building and business development.

IV. Future Development Trends and Challenges

With the continuous advancement of technology and the changing market demand, semi-automatic thick film printing machines will also face new development opportunities and challenges.

1. Intelligent development trend

In the future, semi-automatic thick film printers will be more intelligent, and the automatic intelligent control of the printing process will be realized by introducing artificial intelligence, big data analysis and Internet of Things technology. The printer will be able to automatically collect and analyze various data in the printing process, such as scraper pressure, screen tension, slurry viscosity, drying temperature, etc., and adjust the printing parameters in real time according to these data to ensure the stability and consistency of printing quality. At the same time, through the Internet of Things technology, the printer can be connected to the company's production management system to achieve remote monitoring, fault diagnosis and preventive maintenance, improve the operating efficiency and reliability of the equipment, and reduce the downtime and maintenance cost of the equipment.

2. Further improvement of high precision and high speed

In order to meet the growing demand for high-precision and high-speed printing in the electronics, semiconductor and other industries, semi-automatic thick film printers will continue to make technological innovations and breakthroughs. On the one hand, we will develop higher-precision scraper systems, screen printing technology and positioning systems to further improve printing accuracy and achieve nanometer-level or even higher-level printing resolution; on the other hand, we will optimize the mechanical structure, motion control system and automated transmission device of the printer to increase printing speed and achieve high-speed and efficient printing production to meet the requirements of large-scale industrial production.

3. Environmental protection and sustainable development challenges

Against the backdrop of growing global environmental awareness, the development of semi-automatic thick film printers also needs to consider environmental factors. On the one hand, it is necessary to develop and use more environmentally friendly thick film slurries to reduce the volatilization and emission of harmful chemicals; on the other hand, it is necessary to optimize the energy efficiency of the drying system and other parts to reduce energy consumption and carbon emissions during the printing process. In addition, it is also necessary to improve the cleaning process of the printer, reduce the use of cleaning solvents and the generation of waste, and achieve green and sustainable development of printing production.

4. Talent cultivation and technological innovation challenges

With the continuous development and upgrading of semi-automatic thick film printing machine technology, the demand for professional and technical personnel will become higher and higher. Enterprises need to cultivate compound talents who understand printing technology and multi-disciplinary knowledge such as machinery, electronics, and automatic control to ensure that they can skillfully operate and maintain advanced printing equipment, carry out technological innovation and process optimization. At the same time, printing machine manufacturers also need to continuously increase R&D investment, strengthen cooperation with universities and scientific research institutions, and promote the innovative development of printing technology to meet the challenges of market competition and industry development.

As a powerful assistant for high-precision printing, semi-automatic thick film printers play an important role in modern industrial production and provide key technical support for the development of many industries. With the continuous advancement and innovation of technology, it will continue to make breakthroughs in precision improvement and intelligent development. At the same time, it also needs to actively respond to challenges in environmental protection and talent training to achieve sustainable development and make greater contributions to promoting the upgrading and development of the global manufacturing industry.